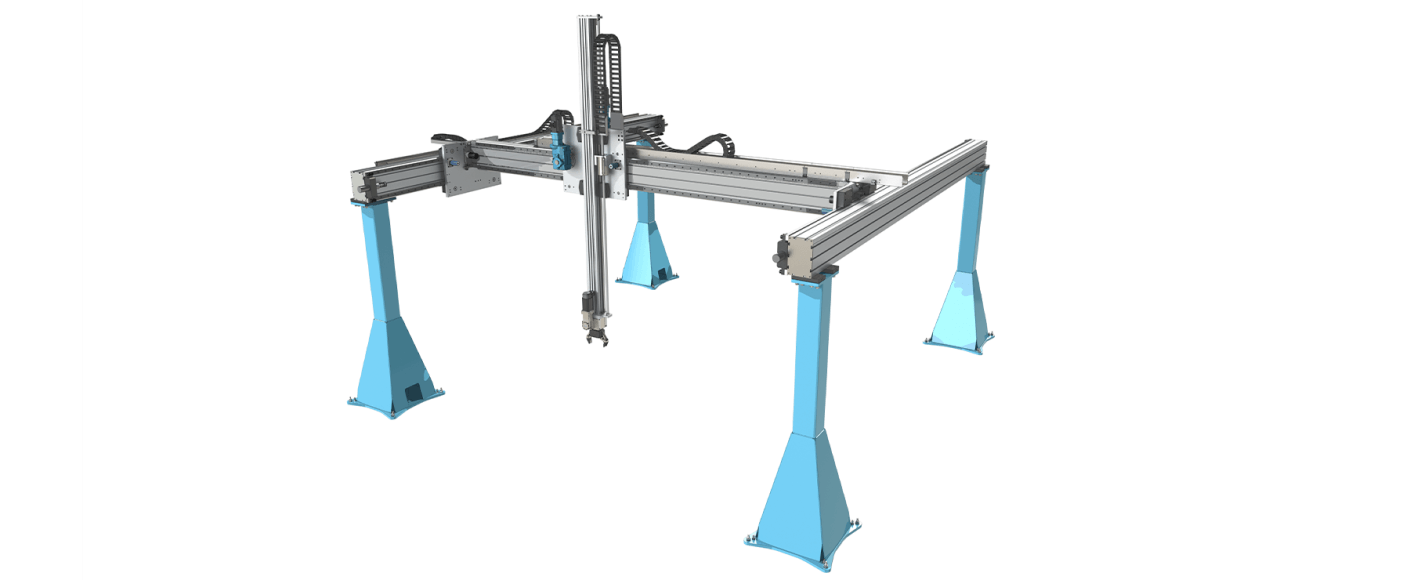

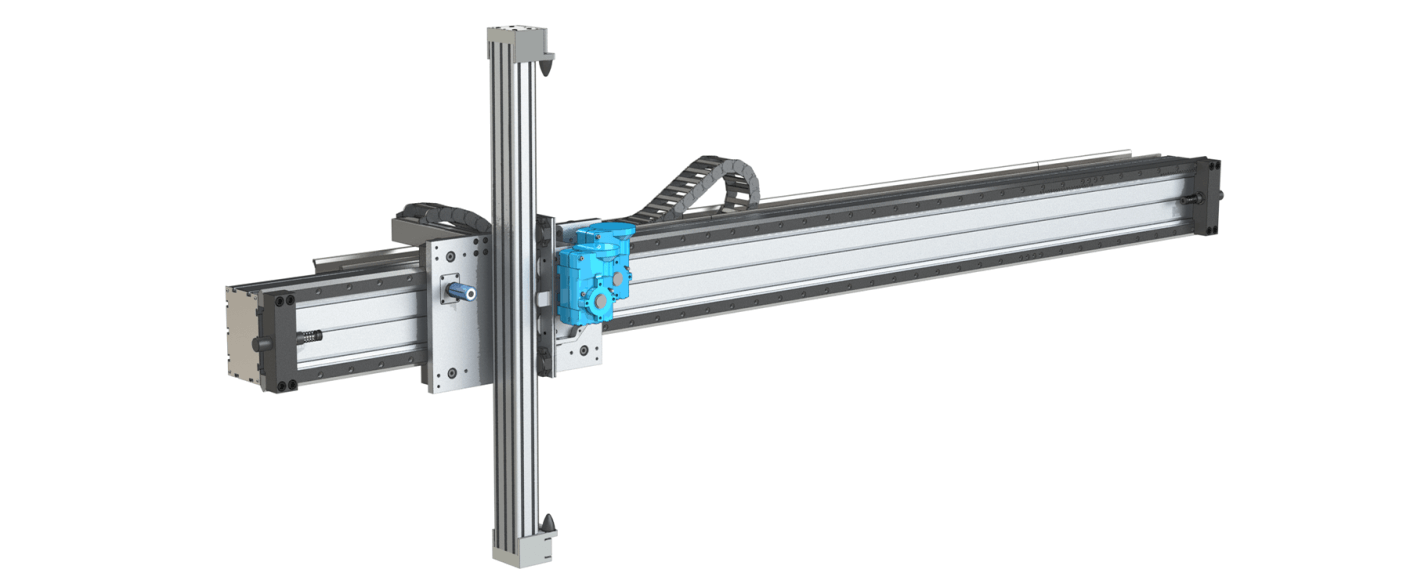

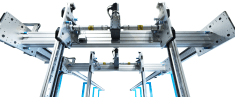

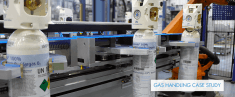

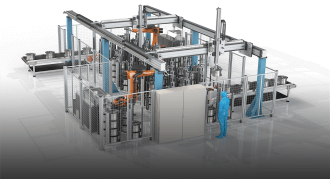

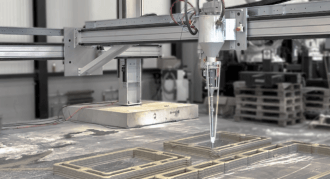

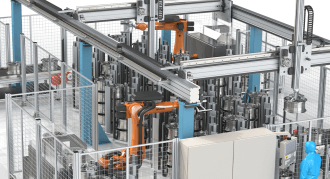

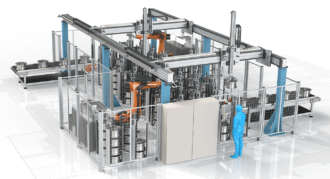

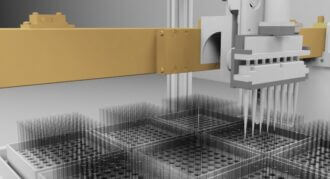

HepcoMotion’s heavy duty V guide system can be configured into multi-axis gantry systems to achieve automation for applications such as palletizing, sorting, and pick & place.

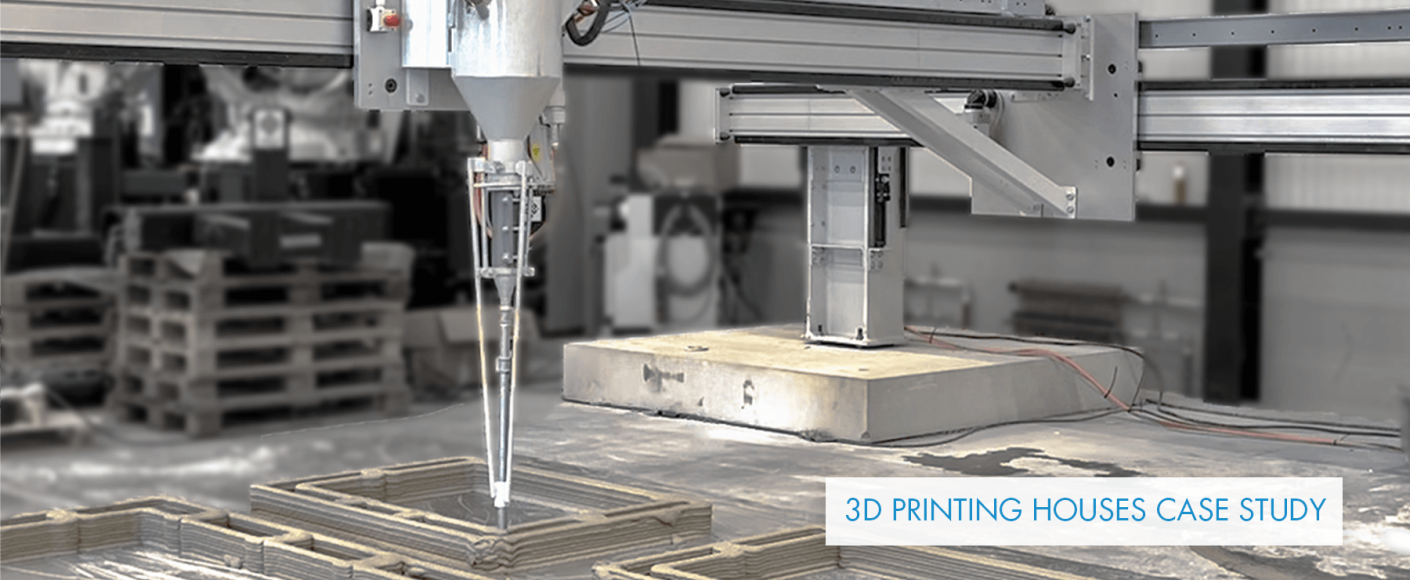

Heavy loads and large work areas – Based on the HDS2 heavy duty range, Hepco’s gantry systems are ideally suited for precisely moving heavy payloads up to 68kN in large work areas.

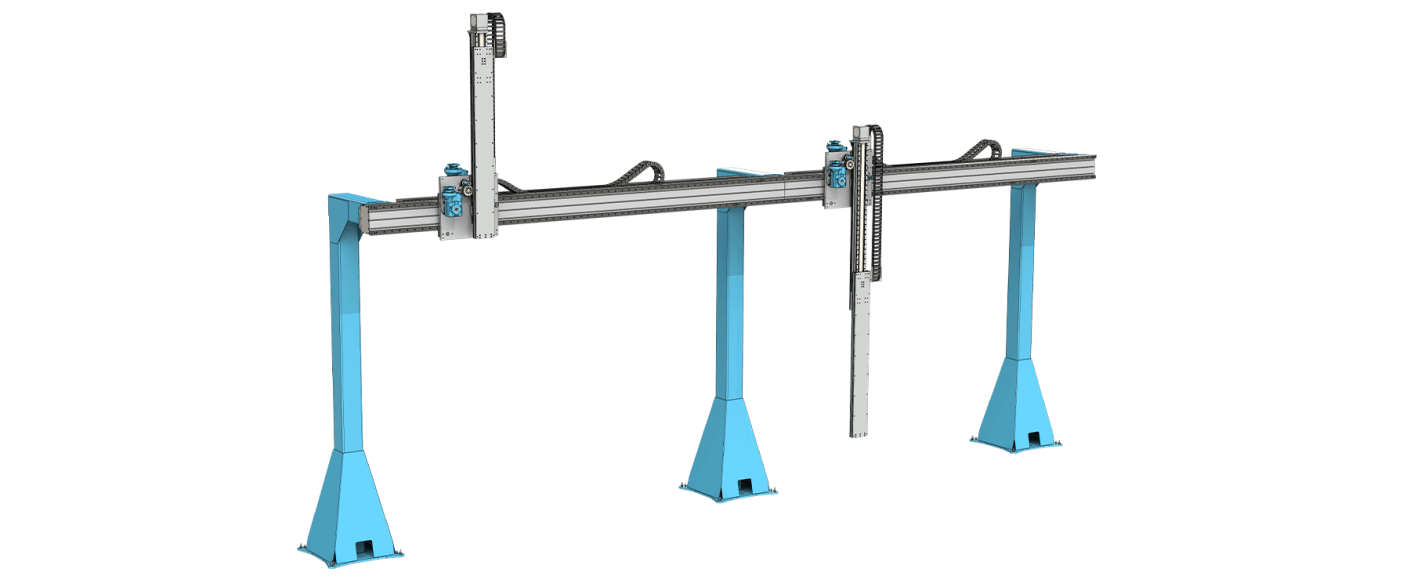

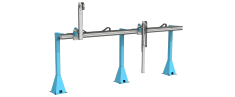

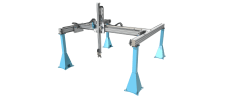

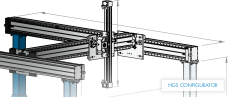

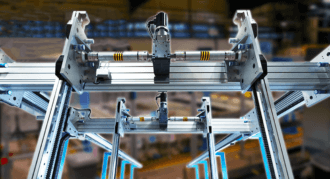

The core of many automated applications – Standard gantry configurations include XZ, XYZ and X. Bespoke designs are also available, saving considerable design time.

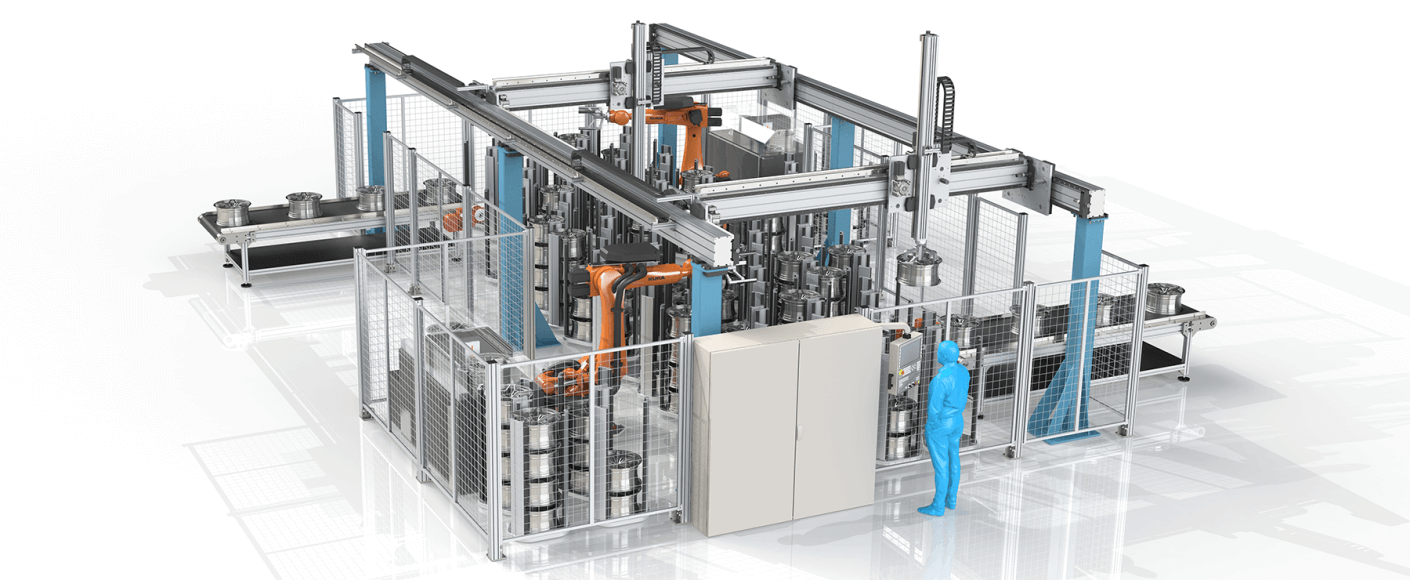

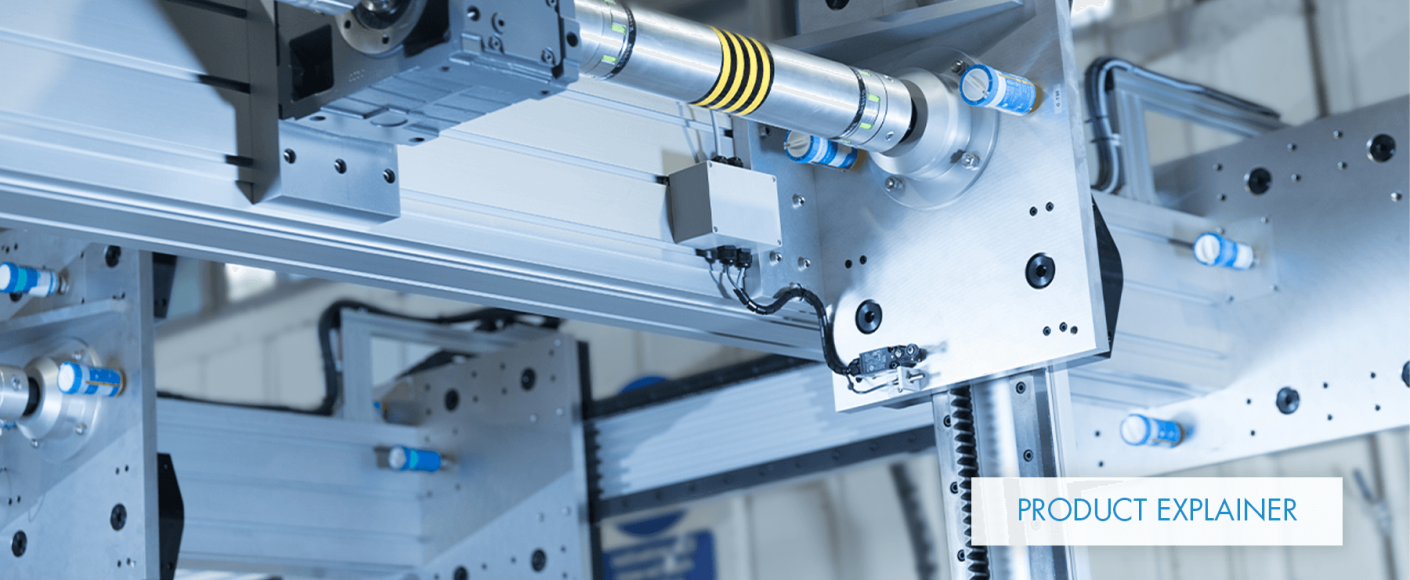

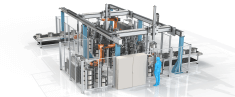

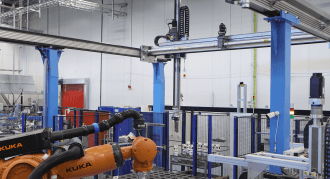

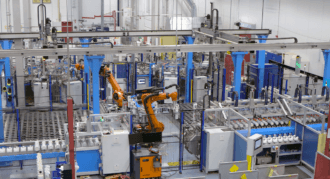

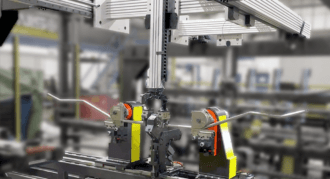

System integration – HepcoMotion gantries can be integrated with existing processes and equipment. Robot integration can greatly increase throughput and reduce manual handling of products and material.

Turnkey gantry solutions – HepcoAutomation can provide standard drive and control systems for any gantry application, managing the project from concept to completion.

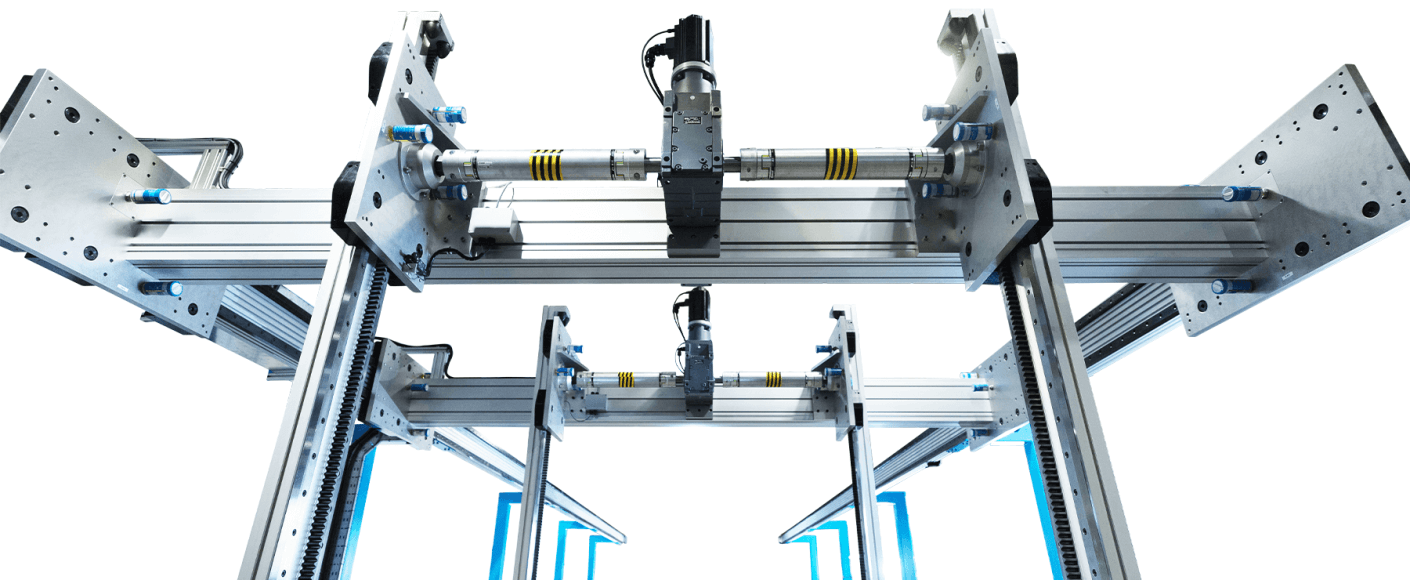

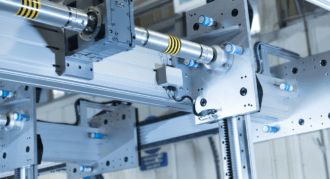

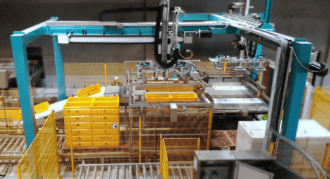

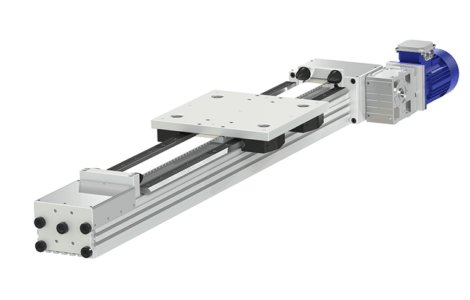

Low maintenance and long life – Hepco’s robust heavy duty V guide system is suitable for the harshest environments, and requires little maintenance, making V guide systems perfect for enclosed systems.

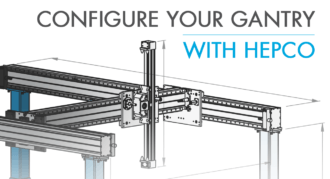

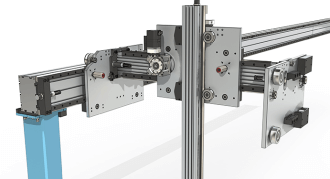

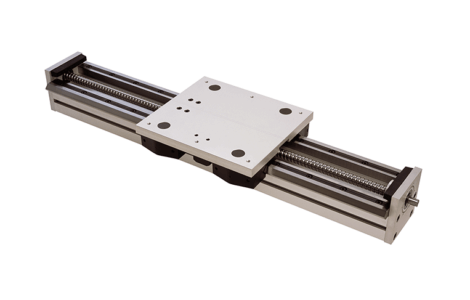

No need for absolute parallelism – The combination of V guide bearings, and roller bearings and flat tracks on a single axis allows for slight discrepancies in the parallelism, reducing setup times.

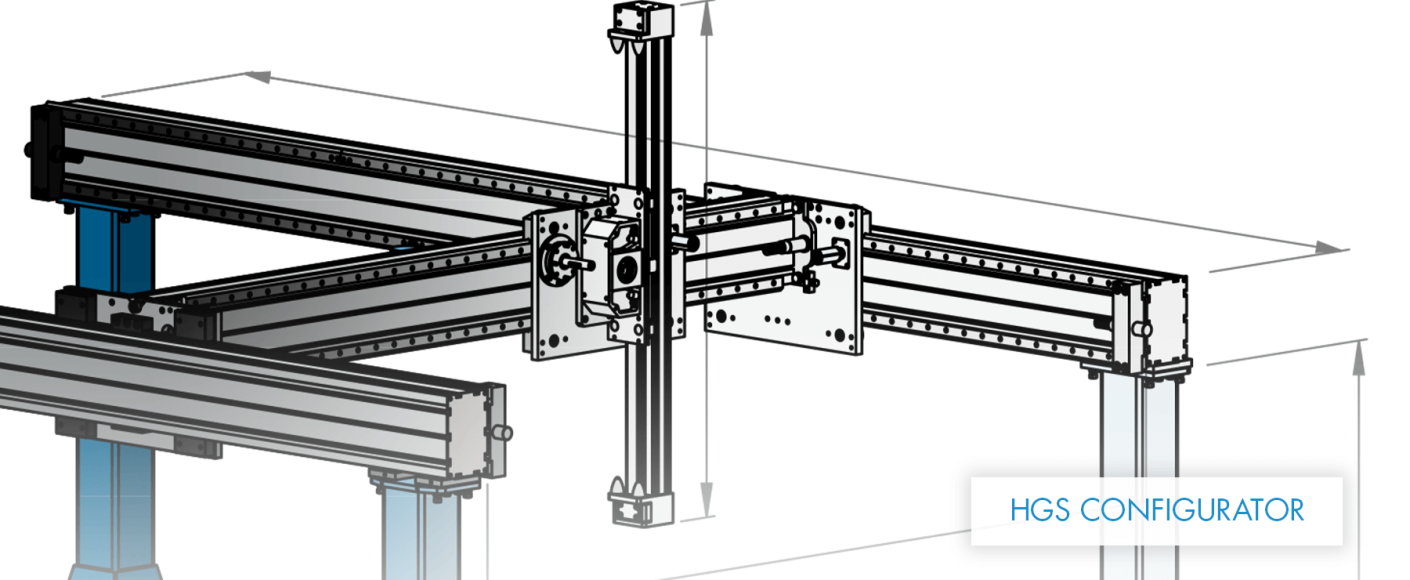

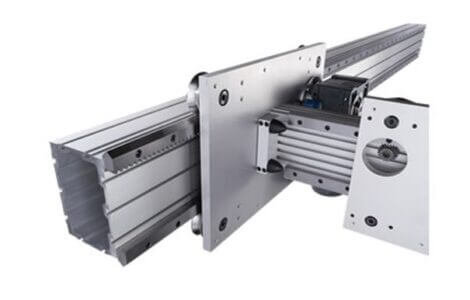

Modular system – Components can be easily combined as and when required, and systems can be extended, increasing flexibility and future-proofing installations.

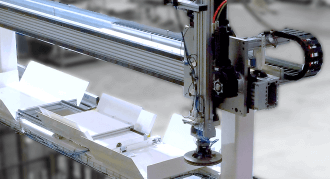

Extensive application support – Alongside a dedicated team of sales & technical design engineers, Hepco’s Gantry System configuration tool will automatically specify an application and generate CAD models as required.

- Wide range of driven gantry systems including belt, ball screw, rack and pinion

- Extensive application support provided, including specification calculator to determine base requirements and performance optimisation

- A range of standard support legs are available to suit the application and space requirements

- Compatible with Hepco’s MCS aluminium profile range

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form