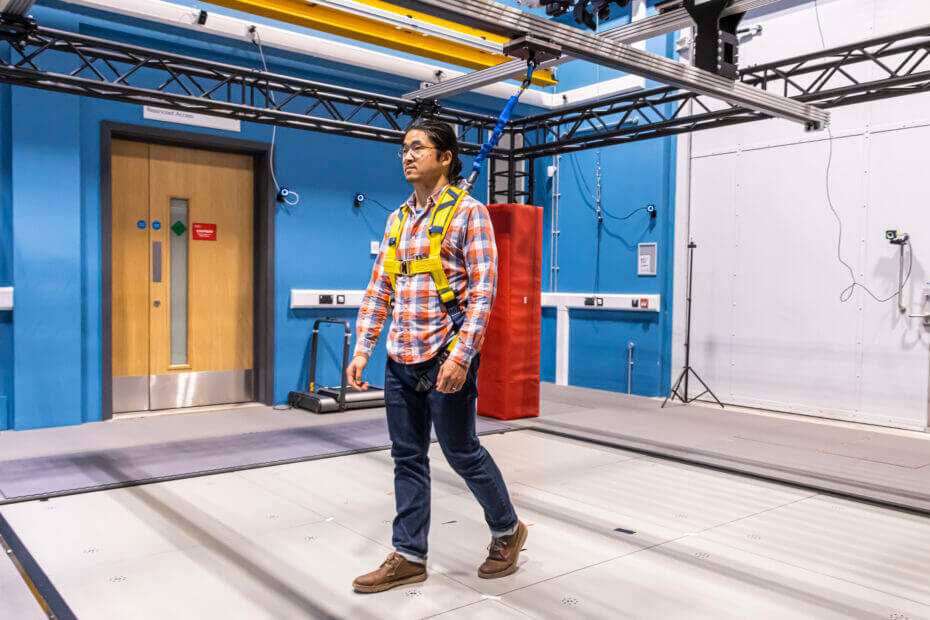

Cutting-edge research at the University of Exeter aiming to train people with Parkinson’s to shift their balance and overcome ‘freezing of gait’ relies on HepcoMotion’s core GV3 linear guide to provide the overhead sliding support system.

Pioneering research for Parkinson’s

Freezing of gait (a feeling that one’s feet are stuck to the floor) is associated with balance problems and anxiety; two areas identified by people with Parkinson’s as priorities for research. This research utilises the world’s largest force-sensing platform and a VSimulator to induce freezing in participants and evaluates the potential influence of weight-shift training on the ability to step from a freeze when a participant walks in a virtual reality environment. A harness is used in conjunction with the overhead guidance system, following the participants’ movements and taking their weight if they stumble to prevent them from falling.

“This research will provide unprecedented access to measurements of walking and freeze events that will undoubtedly progress our understanding of this common symptom of Parkinson’s. Given the potential for this research, it was important for us to work closely with a reliable and technically experienced company to provide the overhead gantry system. ”

Key requirements

Having previously worked with HepcoMotion on several linear applications, the University of Exeter contacted HepcoMotion to supply a multi-axis system that could cover the entire area of the articulated floor. The system also needed to be cost-effective and free running, but still rigid and strong enough for a suspended 150kg load.

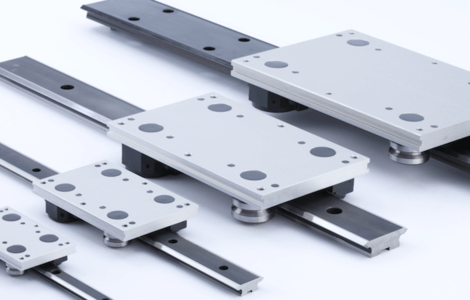

The solution: HepcoMotion’s GV3 system

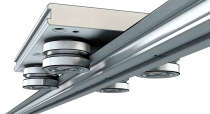

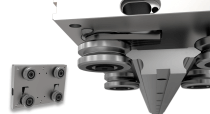

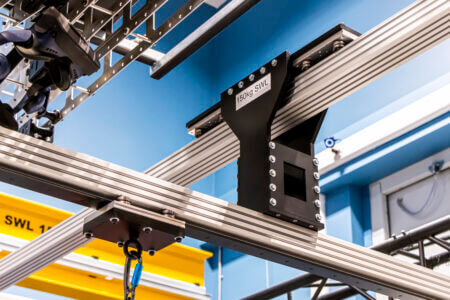

3 x 5 metre GV3 linear guides, mounted to HepcoMotion’s MCS aluminium profiles, provide the basis for the XXY system. GV3 is HepcoMotion’s flagship linear guide system, designed to serve a diverse range of automation and linear applications. 2 x GV3 guides run parallel, with the third working as a cross beam, linking the two guides. On the central beam, the GV3 slide and carriage are mounted underneath the MCS; this is where the harness is attached. The 2 x parallel GV3 slides are 0.5m above the central beam; each beam has a pair of carriages to give greater stability and to share the load.

Bespoke fixing brackets, which connect the parallel beams to the central beam, are attached to these carriage plates. This combination provides the XY motion and unrestricted movement within the required 5x5m envelope, which was key to this application.

Rigidity

Resistance to deflection across the 5-metre lengths was important here; the carriages need to be rigidly guided. Dom Pendry, HepcoMotion Sales Engineer explains: “By mounting the GV3 guides to a MCS profile of suitable cross-sectional area we were able to provide a solution which was rigid enough for this application despite the 5m span and support the weight of a stumbling patient with minimal deflection.”

Low friction for smooth movements

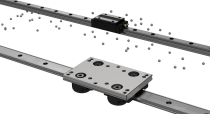

One of the key requirements for this application is that the system needs to be free-running with minimal friction. As the person in the harness moves, it is imperative to have minimal drag on the cable attached to them. This is where HepcoMotion’s GV3 excels thanks to its V guide technology. V guide technology allows customers to back off the eccentric bearings to reduce the preload.

With a minimal payload, the carriages can move more freely, and resistance is reduced.

Capable of high loads

For the vast majority of the time, there will be no load, but the system needs to be robust enough to hold up to 150kg if the person in the harness stumbles, and the system, therefore, has to carry the entire weight of the patient. With a load capacity of over 1000kg, GV3 can confidentially meet this requirement. The gantry is capable of speeds up to 8m/s, however, this system is only required to operate at the walking pace of the person in the harness (approx. 1.5m/s).

The research team expects the first patients with Parkinson’s to be using the system later this year.

“The potential for this research are huge; in addition to Parkinson’s patients, this research also has the potential to help many other medical disciplines such as those suffering from neuropathological, dementia, low mobility, or hip replacements for example. We worked in close collaboration with the technical team at HepcoMotion from initial concept to full specification and final build and they were extremely helpful in solving this challenge, particularly with regards to the low friction requirement.”

Recommended for you

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form