The Application

The trend to produce PCB’s with higher hole densities has put additional accuracy demands on machine manufacturers; a typical 500mm x 600mm board can have between 30,000 to 50,000 individual holes.

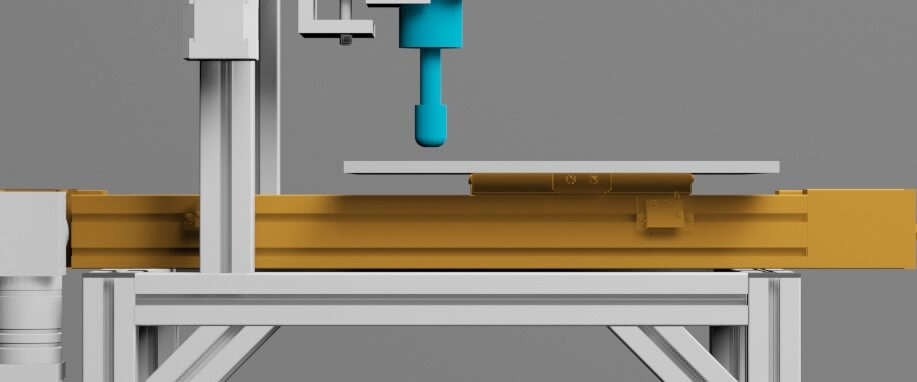

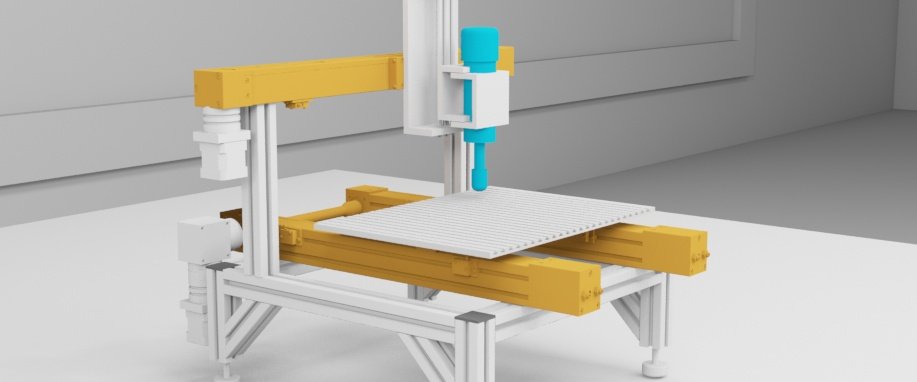

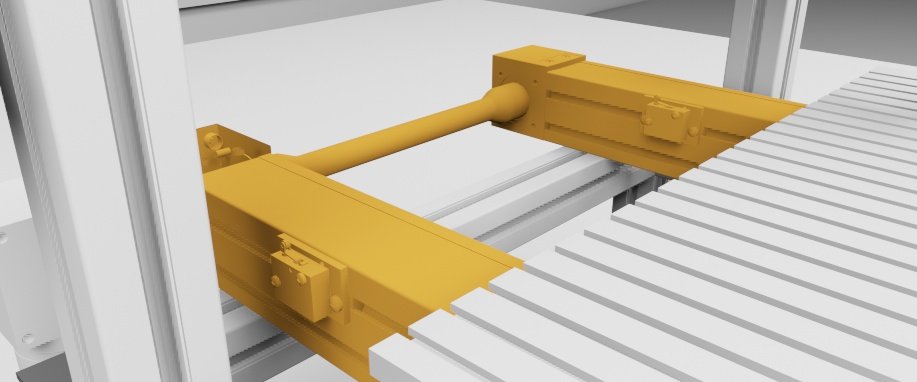

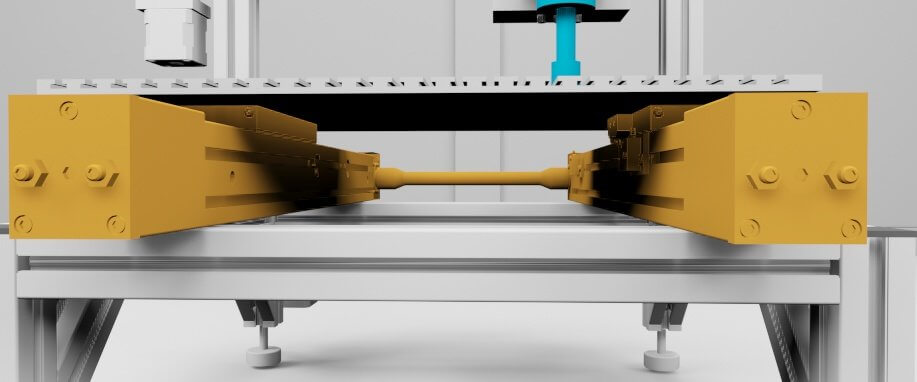

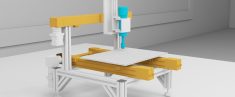

Depending upon the electronic component to be attached holes can be as small as 0.3mm diameter or even less, and be through or blind hole. Conventional ball screw driven products have a key part to play in providing multi axis motion, with the trend to move the board, as opposed to the drill head to cut down on vibration.

Product Solution

High precision ball screw systems relying on rotary encoders to provide the positional feedback will suffice in many cases. For smaller diameter holes laser drilling is preferred to conventional drill bits to eradicate drill wear and hole inaccuracies.

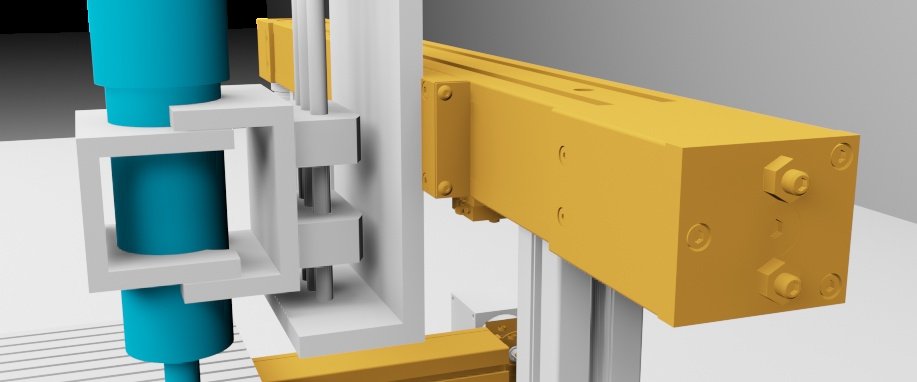

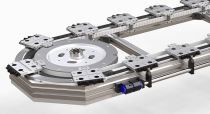

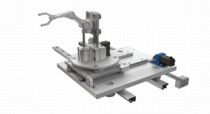

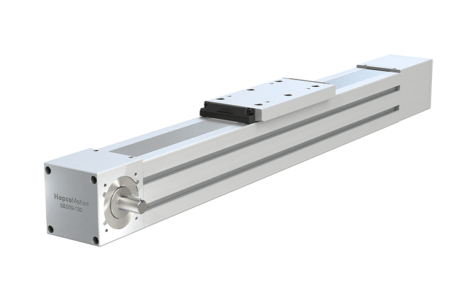

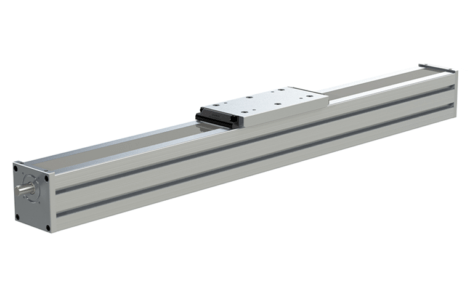

SDM ball screw units or belt driven SBD units, with a linear encoder for positional control, will offer an easy to integrate solution depending on hole size and accuracy required.

A servo motor with precision gear head is the usual choice for the XY axis drive to move the board, whilst the air driven drill head can be positioned again using an SDM ball screw unit.

Recommended for you

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form