The Application

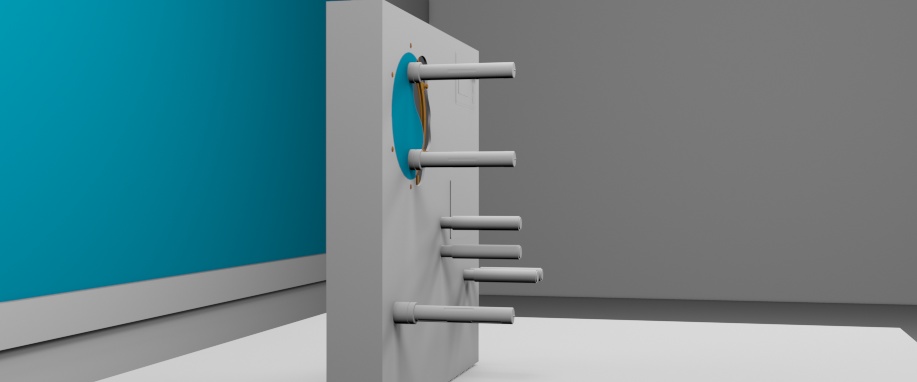

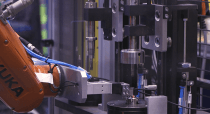

Linear systems are used extensively on printing machines but the most common motion requirement is rotary. The two mandrels fitted to the turret will need to be indexed so that when a mandrel is free it can be wound, in this case, with finished labels.

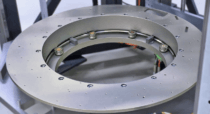

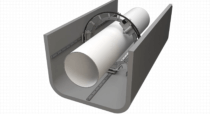

This principle can be scaled up to much larger rolls opening up the possibility to use V ring systems as an option to slewing rings. V ring users will be all too familiar with the inherent low installation and running costs this arrangement provides.

Product Solution

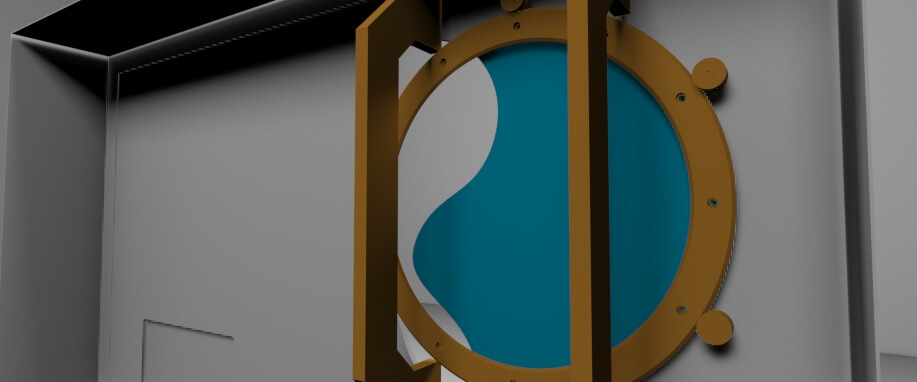

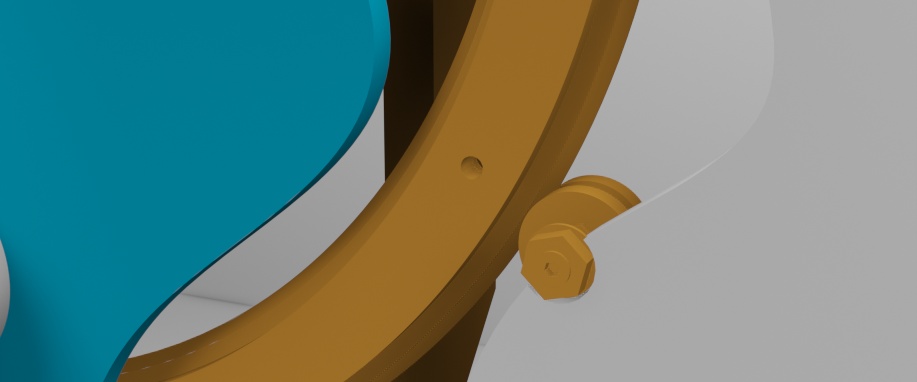

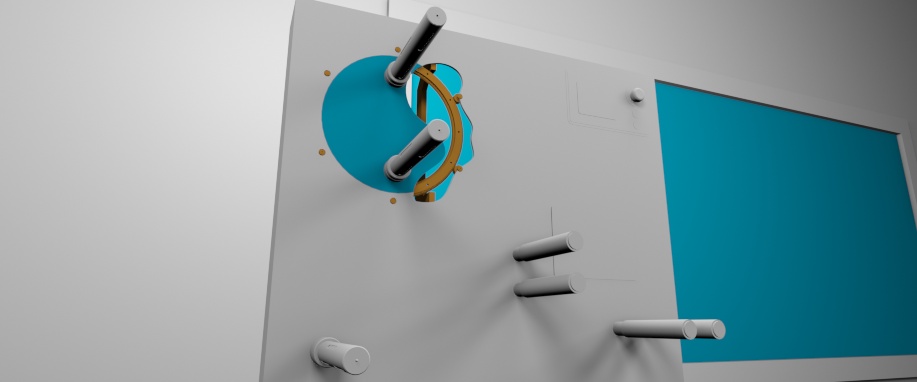

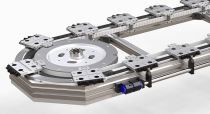

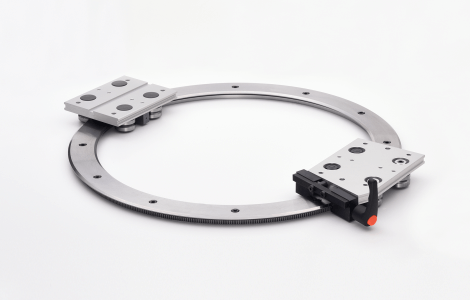

The PRT2 V ring design with 6 supporting V groove bearings replaced a traditional bearing arrangement where the bearing was fitted to a central shaft. This over complicated the drive to the mandrels and the whole arrangement took too long to assemble. The V ring allows services to be routed in the centre with an internal gear cut into the ring to keep the system compact.

The centrally located servomotor provides the power to the drive pinions, in turn, linked by a timing belt. V ring systems offer exceptional space savings with the services centrally routed allowing a simpler lower cost design to be used.

Recommended for you

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form