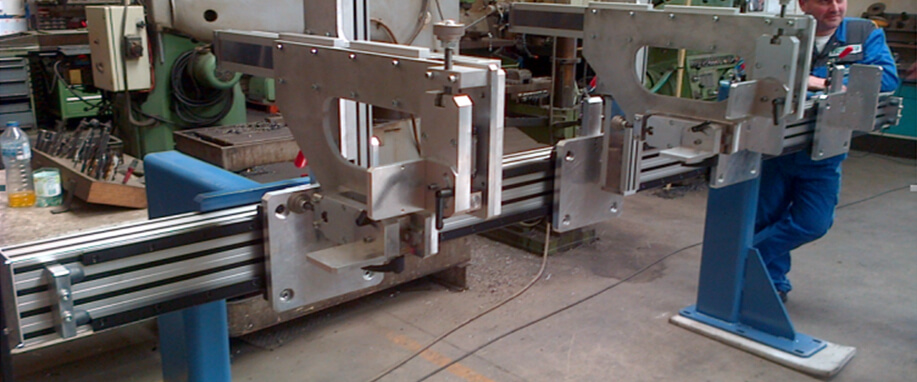

This French special purpose machine builder needed to measure the flatness of 8m long steel rails in a number of positions along their length.

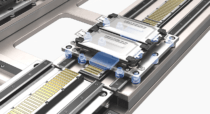

To achieve this measuring sensors were positioned and adjusted X, Z and Y directions. The longitudinal X beam was 3m long and the steel rail (not in picture) was indexed into position so effectively 8 readings were taken over the 8m length. The key requirement for the sensors was rigidity, ease of adjustment and, where the X axis is concerned, inherently good straightness.

Solution

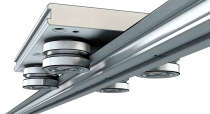

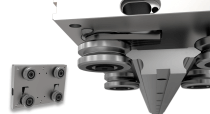

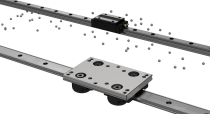

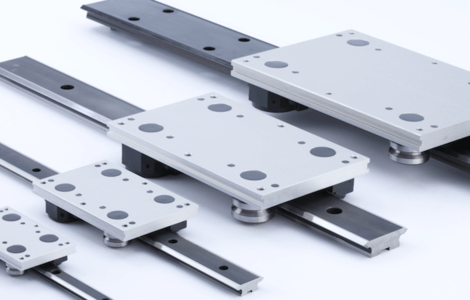

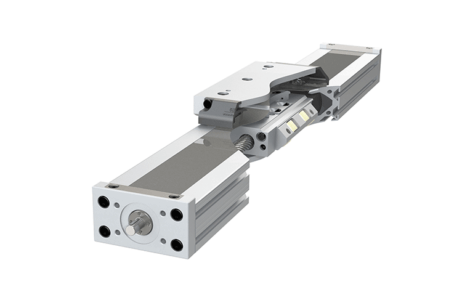

For the X axis GV3 single edge slides mounted to the 160mm section of a strong MCS profile 80mm x 160mm x 3.2 m long. This provided low friction guidance with good rigidity for the 4 carriages carrying the Z, Y guidance systems. PSD80 units x 700mm long with screw adjustment, through a hand wheel, were used to move the sensors in the Z,Y directions. Once set to a known datum position the flatness reading of the rail was taken.

Result

An easy to use manually operated fixture offering good rigidity with simple adjustment. This application demonstrates the versatility of the HepcoMotion product range and how three standard products can be put together to provide a highly efficient cost effective solution.

Recommended for you

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form